Current-carrying components

The LEDFix® system is our (highly conductive) combination for current-carrying mounting technology in SELV / low-voltage applications in accordance with VDE standard DIN EN 61140.

Our LEDFix® solution

The LEDFix® system combines mechanical fastening and electrical contacting in the SELV range (low-voltage applications). Similar to purely mechanical cable fastening systems, the LEDFix® system is also divided into the three major sub-areas of ceiling, room and object.

As you have come to expect from ERS products, the LEDFix® system is completely tool-less to install by the end user, with only minor pre-assembly work at the factory.

The cabling with our special HCF power cables ensures almost loss-free energy transmission with simultaneous high mechanical load capacity. The height adjustment is carried out analogously to the purely mechanical cable systems via a 3-ball clamping mechanism, except that this is completely electrically insulated.

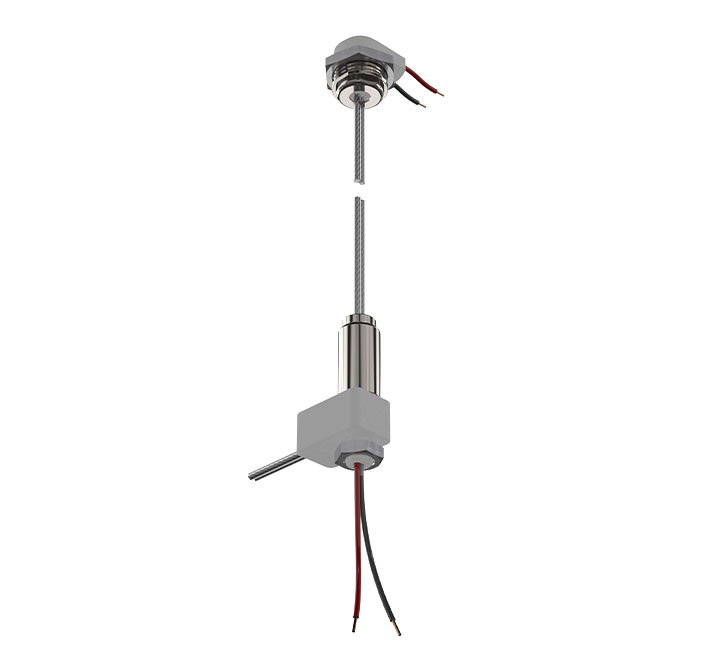

Several interfaces between height adjustment/contacting on the luminaire and HCF current cable on the one hand, and HCF current cable with cable base and the SystemBase located in the technical support on the other hand, offer the possibility of optimum separation of the components for packaging and shipping.

Why you should benefit from our

Benefit from system solutions

- Combination of mechanical fastening and electrical contacting

- Can be installed by the end user without the use of tools

- Loss-free energy transmission due to special HCF power cables

- Flexible height adjustment and contacting on the luminaire possible

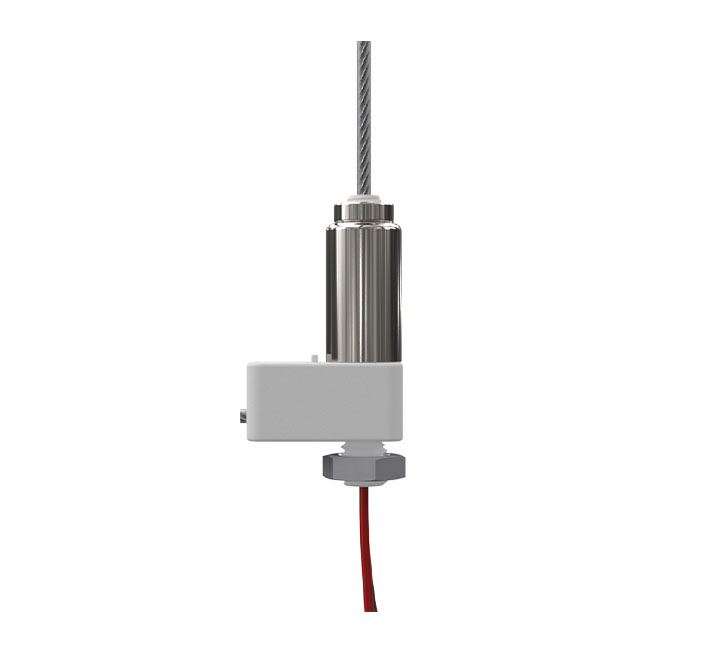

LEDFix® system 1-pole

LEDFix® system 2-pole

Ceiling

Manufacturer:

Screw connection of the SystemBasis components in the equipment rack You only need one hole for a threaded screw connection. Establish contact on the supply side using a PushlN terminal (rigid conductor).

User:

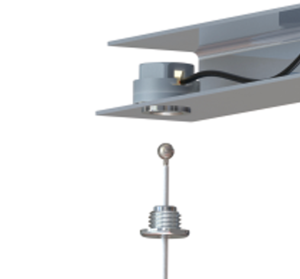

Easy screwing of the HCF conductor rope with rope base into the equipment support. When tightening, contact is made between the spring clip in the system base and the ball at the end of the HCF current cable.

Room

Manufacturer:

HCF power cable and cable base can be supplied loose with the luminaire. No need to "wire" between the luminaire and the technical support already at the factory. The HCF power cable is a mechanically heavy-duty insulated conductor. You do NOT need any SUPPLY to your luminaire.

User:

Simple screwing of HCF current rope with rope base into the technical support. There is no difference in handling compared to the known rope suspension systems and thus no source of error due to incorrect operation.

Object

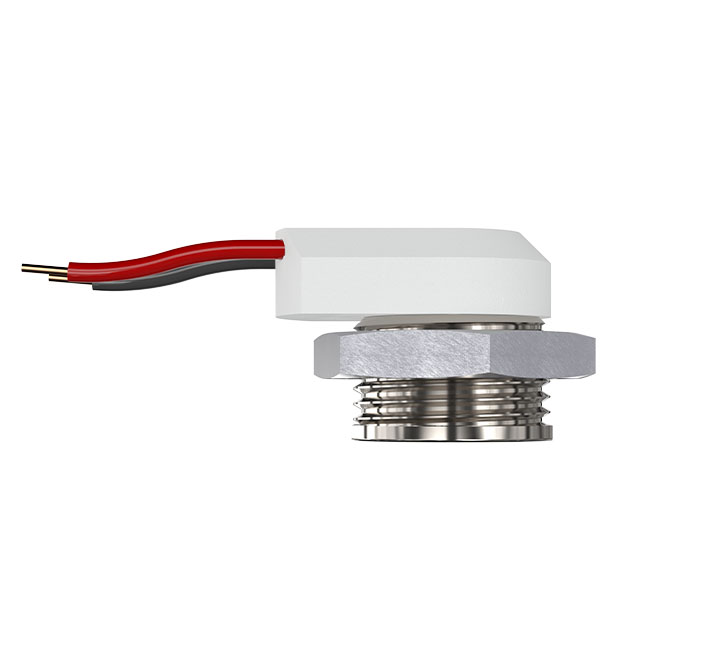

Manufacturer:

Pre-assembly of the contacting box already at the factory. The contacting on the luminaire side is made by means of a PushlN terminal (rigid conductor). Due to the possibility of including the LEDFix® loose in the mounting set, the packaging and shipping of your luminaire is significantly less complex, as no components protrude as would be the case with a pre-assembled RopeFix on the luminaire housing.

User:

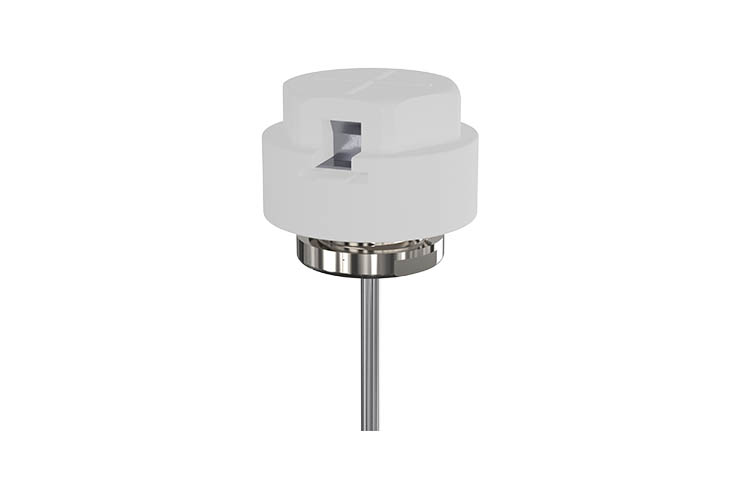

Simple insertion of the HCF power cable into the LEDFix®, as users know it from the RopFix cable hangers. Afterwards, the LEDFix® with the HCF current cable can be pushed sideways into the contacting box and locks into place independently. The user can now adjust the height of the luminaire in the usual way. In the last step, the contact is made by pressing in a "switch".

Matching system components for LEDFix®

RopeFix®

Our systems

Track & Rail system

Lead-free system

Stainless steel system

Rigging system

Universal system

AcousticsFix® system

Are you interested in the LEDFix® system?

Our experts will be happy to advise you and together find the best solution for your company.

Innovative fastening technology "Made in Germany":

From development and design to manufacturing and quality assurance, all development and production processes take place at the Lorsch site.